Fast Delivery, Custom Sizes. Send Inquiry we will reply within 24 hours

Global Supplier of BOPET Film: High Quality, Competitive Prices

Contact us today for a free sample and a quick quote!

Direct Manufacturer PricingBy purchasing directly from the manufacturer, you eliminate middlemen costs, ensuring you get the most competitive prices in the market.

Large Stock, Ready to ShipWe maintain a large stock of BOPET films, enabling us to fulfill orders promptly, ensuring no delays in your supply chain.

Customizable SolutionsWe offer fully customizable BOPET film options, including thickness, width, and finish, ensuring that your product meets exact industry specifications.

Flexible Order QuantitiesWhether you need a small trial batch or a large-volume order, we offer flexible order quantities to meet your specific requirements.

BOPET Film Product Range

BOPET Customization Service Process

Start Your BOPET Film Project

Send us your customization requirements through the online form, and our technicians will contact you within 2 hours

Step-1: Requirement Consultation

Our customization process starts with a detailed consultation to understand your specific requirements. You can reach out to online form to discuss the dimensions, thickness, physical properties, and functional requirements for your application.

Step-2: Technical Evaluation & Recommendations

Our technical team will evaluate your needs and provide expert recommendations to ensure the best product design and performance. We will help you choose the right BOPET film type based on your specifications and desired outcomes.

Step-3: Sample Production & Approval

We’ll produce a sample of the customized BOPET film based on your requirements and send it for your review and approval. You can test the sample and provide feedback until the product meets your exact expectations.

Step-4: Mass Production & Quality Control

Once the sample is approved, we begin mass production. Using advanced equipment and strict quality control processes, we ensure every batch of BOPET film meets the highest standards for quality and consistency.

Step-5: Packaging & Logistics

We offer secure packaging solutions to protect your products during transport. Working with trusted logistics partners, we ensure fast and safe delivery to any global destination, so your products arrive on time and in perfect condition.

Step-6: After-Sales Support

Our service doesn’t end with delivery. Our technical support team is available to assist with any post-sale inquiries, ensuring that your BOPET film performs as expected and helping to resolve any issues that may arise.

Our advantage

Why Choose us

We are your trusted partner for all your BOPET film needs. Our products are certified for safety, backed by internationally recognized standards like UL, ROHS, ISO9001, and ISO14001, ensuring you receive reliable and eco-friendly solutions.

UL & ROHS Certified

Our BOPET films are UL-certified for safety by the US laboratory and meet the stringent environmental requirements of the EU’s ROHS standards, ensuring your products are both safe and eco-friendly.

ISO9001 & ISO14001 Certified

We have passed rigorous audits from recognized institutions to obtain ISO9001 for quality management and ISO14001 for environmental management, ensuring strict control over quality and sustainability in our production process.

Global Clientele

We are a trusted partner for top companies across over 50 countries, known for our reliability, quality, and ability to meet global demand.

Flexible Order Quantities

From small batches to large-scale orders, we offer flexible production capabilities to suit businesses of all sizes, ensuring you receive exactly what you need when you need it.

About Us

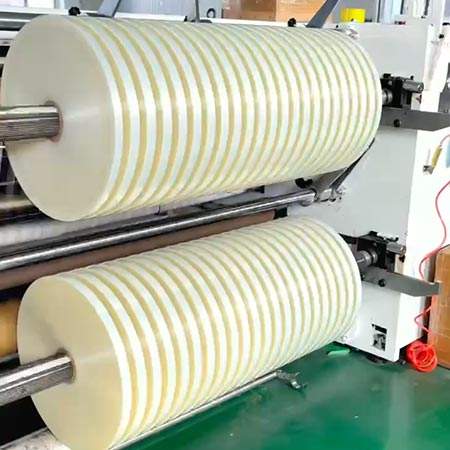

Yi Shuya (Shandong) New Material Co., Ltd is a company focusing on the research and development, processing, sales, new material technology promotion services, import and export of plastic products. The company was established in 2019 and is located in Weifang, Shandong. The factory covers an area of about 10,000 square meters and currently has more than 100 employees.

It is amazing that Yishuya provides high-quality products to countless stable customers on all continents of the world. Our main products include BOPET polyester film, BOPP film, CPP film, PVC film, PE film, and PET reflective tape. In addition, Yishuya can help you customize your products, cut and slit your products, and package them for port transportation, so you can achieve one-stop procurement of a series of products.

Our Factory