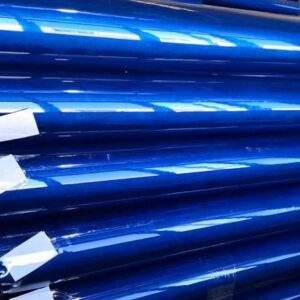

PET blue film is a protective film based on blue polyester film, usually coated with glue on one side. It has many advantages, including wear resistance, scratch resistance, dust resistance, high temperature sticky residue resistance, high gloss elasticity, and good weather resistance (high temperature/high humidity/solvent). The application range is very wide, and it is commonly used in the temporary fixation of various household appliances and electronic products, as well as the bonding and fixation of precision (optical) components and other products during the production process. Especially in the plastic packaging industry, silicone is one of the most widely used adhesives, and its performance basically meets the bonding requirements of plastic films and protective films, so PET blue film is also commonly used in this field.In addition, PET blue film is also used for laminating foam, graphite waste discharge, laminating batteries, etc. Compared with transparent PET protective film, colored protective film will be easier to distinguish after laminating. During the battery packaging process, in order to enhance the adhesion between the blue film and the battery aluminum shell and the battery stability, a plasma surface treatment (cleaning) machine will be used to treat the blue film. PET blue film, as a mainstream battery protection material, has excellent physical and chemical properties, such as acid and alkali resistance, corrosion resistance, high pressure resistance, no residual glue, explosion-proof and flame retardant, etc. It is a very good choice as a battery protection film.

Description

PET blue film characteristics

- High light transmittance, and good quality, to prevent product scratches

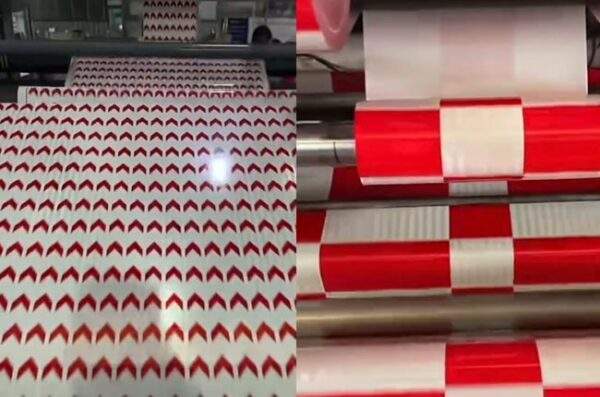

- Reticulated dot structure, which can disperse pressure and reduce the chance of direct damage by impurities and crystal points

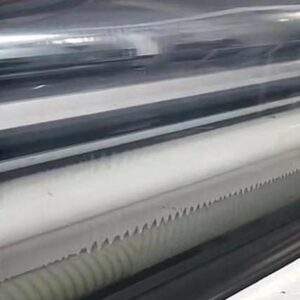

- Easy to fit and peel, improve the efficiency of automated assembly

- Self-developed glue, the glue system is silicone, the viscosity is very stable, and there is no residual glue after tearing it off

- Easy to die-cut, very suitable for use in the electronics manufacturing industry

- Excellent cleanliness, processed in a 1000-level clean environment