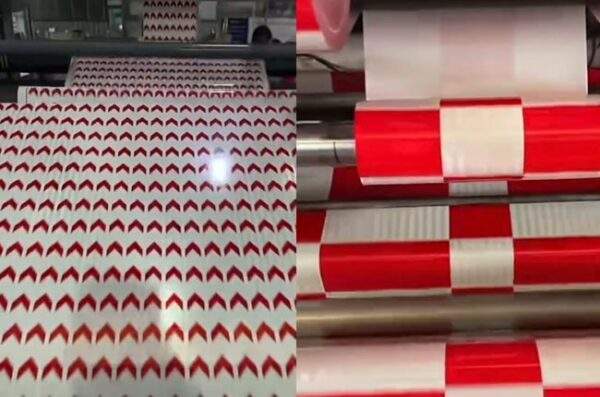

PET high-transmittance film

It is a polyester film material with high transparency, the full name is polyethylene terephthalate film. Compared with ordinary PET, high-transmittance PET has higher transparency, low refractive index, higher flexibility and easy processing. It is widely used in the fields of display screens, backlight modules, touch screens, optical films, etc. of electronic products. High-transmittance PET is usually made of PET raw materials through multiple processes, and has excellent mechanical properties, thermal stability, anti-frost and chemical corrosion resistance. In addition, high-transmittance protective film is a film material with high transparency and protective function, usually made of PET material, and is a high-tech protective material. As a high-transmittance protective film, it has the function of reducing or eliminating the reflected light of optical surfaces such as prisms and plane mirrors, thereby increasing the light transmittance of these components and making the light level present to the user's eyes.

Description

PET high-transmittance film characteristics

- Light transmittance: Put the mobile phone protective film in front of your eyes and use the protective film to see that the protective film with high light transmittance is of better quality than the protective film with low light transmittance.

- No adhesive residue: Peel off the No. 1 label and observe whether there is any adhesive residue. No adhesive residue is better.

- Prevent scratches: After applying the film, scratch it a few times with your fingernails to avoid scratches.