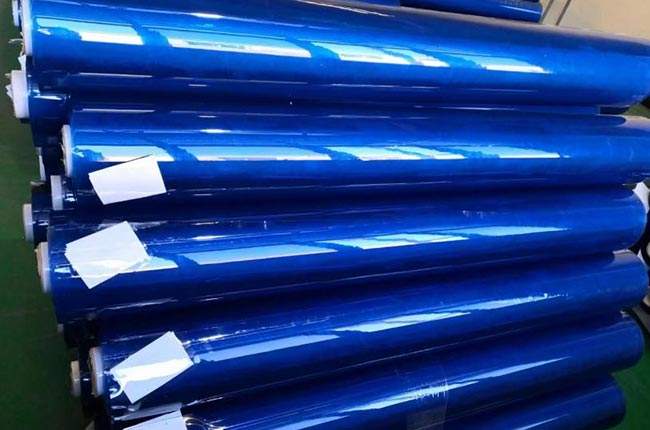

PVC film

PVC film, the main component is polyvinyl chloride. It is a synthetic material that is favored for its excellent performance and wide application. In the manufacturing process of PVC film, in addition to the main polyvinyl chloride component, other ingredients are added to enhance its heat resistance, toughness, ductility, etc. The structure of this film includes the top layer of paint, the middle polyvinyl chloride and the bottom layer of back-coated adhesive. Due to its diverse uses and good performance, PVC film ranks second in global usage among various synthetic materials and is an ideal material for producing three-dimensional surface films.

Product advantages

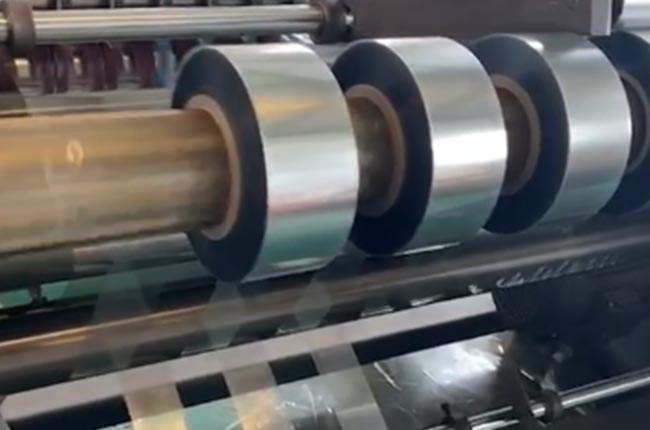

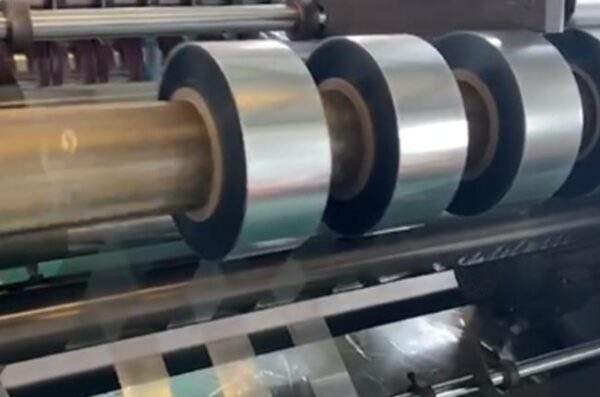

Excellent strength and durability

Good transparency, brightness and flatness, and adjustable shrinkage

Green and environmentally friendly, free of toxic substances, and environmentally friendly

Strong corrosion resistance and good plasticity

Customize your needs and get a quote

Contact us through the form and send us your needs or the products you want to inquire about.

Our product experts will reach out to you within 2 hours.

View products

Application Areas

The product has excellent physical and chemical properties, dimensional stability, transparency, wear resistance, recyclability, and is resistant to high temperatures, low temperatures, oils, moisture, and chemicals. It has good adhesion to some inks or silicone oils and silver pastes, so it is widely used in different fields

FAQ

PVC film is a film material made of polyvinyl chloride (PVC for short). This material is formed by the polymerization of vinyl chloride monomer generated by the reaction of ethylene and chlorine. In the production process of PVC film, different hardness and softness of materials can be obtained by adjusting the processing method and controlling the content of plasticizer.

PVC film has non-flammability, high strength, climate change resistance and excellent geometric stability. It has strong resistance to oxidants, reducing agents and strong acids, but is not suitable for environments in contact with strong oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, as well as aromatic hydrocarbons and chlorinated hydrocarbons.