PORDUCTS

- ×

BOPP film

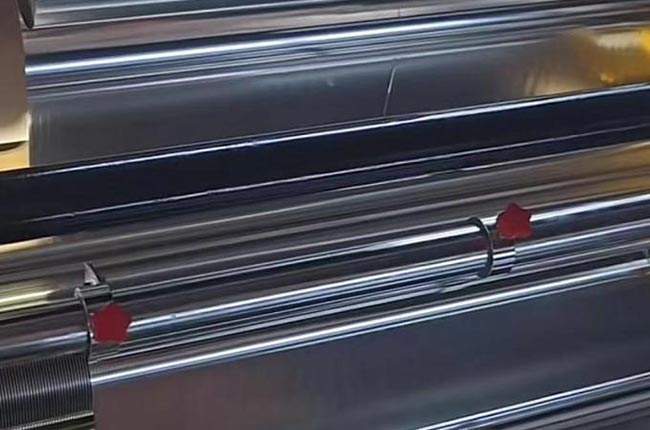

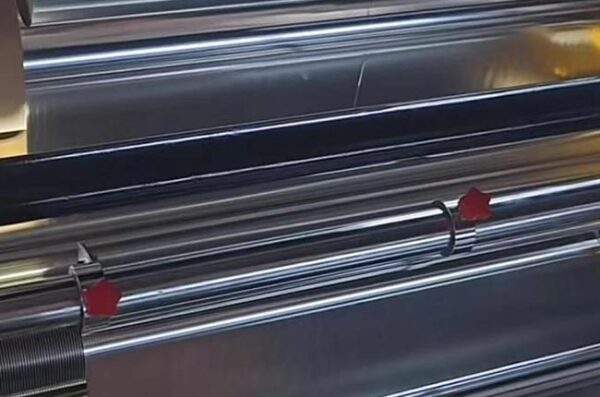

BOPP film is biaxially oriented polypropylene film, referred to as BOPP, which is a kind of plastic film. It is made by coextruding polypropylene particles into sheets and then stretching them in both the longitudinal and transverse directions. BOPP film has the advantages of high tensile strength, good barrier properties, high transparency, etc., and its application is developing in the direction of diversification, high quality, multi-layer, and asymmetric composite. There are many types of BOPP films, including ordinary biaxially oriented polypropylene film, heat-sealed biaxially oriented polypropylene film, cigarette packaging film, biaxially oriented polypropylene pearlescent film, biaxially oriented polypropylene metallized film, matte film, copy book film, laser molded film, anti-counterfeiting film and paper ball film.

Category: BOPP filmOpen full product page - ×

BOPP high-gloss film

BOPP high-gloss film is a film composite product with a glossiness of more than 100. It is usually composed of several parts such as polyester film (PET film), surface treatment agent, ink, adhesive, PVC film, etc., and is obtained by compounding the various parts with high-tech production equipment. The surface effect of this film is crystal clear, colorful, and long-lasting. It has a soft feel and colorful surface patterns. It is a safe and environmentally friendly building material that can choose patterns according to the changes in the color perception of the times. BOPP high-gloss film does not require electroplating or painting, saves energy, and eliminates public pollution problems such as waste liquid and waste gas. Therefore, it is widely used in moisture-proof, anti-corrosion, and non-flammable occasions.

Category: BOPP filmOpen full product page - ×

BOPP matte film

BOPP matte film is a special film material, the main feature of which is to achieve the matte effect by absorbing and scattering light, that is, reducing or eliminating the gloss of the surface, making it appear matte or matte. This film material is usually used to improve the grade of printed products, especially in occasions where high-end packaging is required, such as boxed food or high-end packaging. The use of BOPP matte film can not only increase the visual appeal of printed products, but also provide better protection and extend the shelf life of products.

Category: BOPP filmOpen full product page - ×

BOPP heat-sealing film

BOPP heat-sealing film is a plastic film. It is one of the basic varieties of BOPP film (biaxially oriented polypropylene film) and is mainly used for printing, composite bag making or wrapping packaging. BOPP heat-sealing film is divided into single-sided heat-sealing film and double-sided heat-sealing film. After the single-sided heat-sealing film is printed with a pattern on the non-heat-sealing layer, it is composited with PE, BOPP and aluminum foil to make bags for food, tea, beverages, etc. Double-sided heat-sealing film is directly heat-sealed to form packaging for food, textiles, audio-visual products, poker, etc., requiring the film to have good heat-sealing properties.

Category: BOPP filmOpen full product page - ×

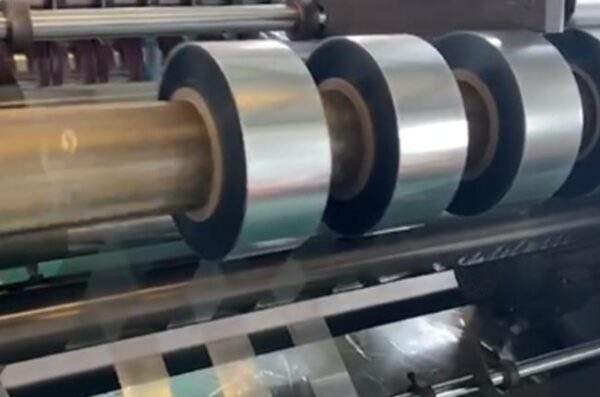

Bopp tape film

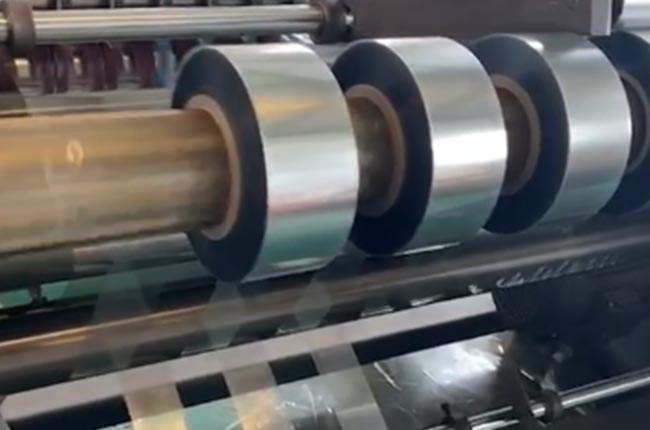

BOPP tape film is a kind of tape with BOPP (Biaxially Oriented Polypropylene) film as the base material, and pressure-sensitive adhesive latex is evenly applied after heating to form an adhesive layer. This kind of tape is an indispensable item for light industrial enterprises, companies, and personal life. After the BOPP original film is treated with high-voltage corona, one side of the surface becomes rough, and then glue is applied on it to form a mother roll, and then it is cut into small rolls of varying specifications by a slitting machine, which is the tape we use daily. The main component of the pressure-sensitive adhesive latex is butyl ester, which makes the BOPP tape have excellent adhesion and ease of use.

Category: BOPP filmOpen full product page - ×

BOPP pearlescent film

BOPP pearlescent film is a film made of polypropylene resin as the main raw material, by adding calcium carbonate and pearlescent pigments, and through a biaxial stretching process. The specific gravity of this film is as light as about 0.7, which is much lower than the specific gravity of polypropylene of 0.9, and has good decorative properties and excellent performance. The production of pearlescent film adopts the mechanical foaming method, which makes it light, non-toxic, odorless, moisture-proof, etc. At the same time, it also has the advantages of high transparency, good gloss, good barrier properties, high impact strength, and low temperature resistance. Due to its good physical stability, mechanical strength and air tightness, BOPP pearlescent film is widely used in the field of printing and packaging, such as cold drink packaging (such as ice cream, heat-sealed labels, sweets, biscuits, flavored snacks, etc.), providing beautiful and practical solutions for the packaging industry.

Category: BOPP filmOpen full product page - ×

BOPP anti-fog film

BOPP anti-fog film is a transparent BOPP functional film with double-sided corona, double-sided heat sealing and double-sided anti-fog. In addition, BOPP anti-fog film also has excellent transparency and durability, and is suitable for various packaging occasions, such as food packaging, electronic product protection, etc., and can significantly improve the aesthetics and practicality of packaging. Due to its excellent anti-fog performance, BOPP anti-fog film is particularly suitable for applications where high transparency and the prevention of moisture condensation are required, such as the fresh-keeping packaging of vegetables, fruits and other foods.

Category: BOPP filmOpen full product page - ×

BOPP printing film

BOPP printing film is a biaxially oriented polypropylene film, referred to as BOPP. It is a plastic film made by coextruding polypropylene particles into sheets and then stretching them in both the longitudinal and transverse directions. This film has many advantages, including light weight, non-toxic, odorless, moisture-proof, high mechanical strength, good dimensional stability, good printing performance, good transparency, etc. Therefore, BOPP printing film is widely used in the packaging of food, candy, cigarettes, tea, juice, milk, textiles, etc., and enjoys the reputation of “Queen of Packaging”. It has a wide range of applications, low pollution to the environment, and its protection of forest natural resources makes it a more popular packaging material than paper and polyvinyl chloride.

Category: BOPP filmOpen full product page

- ×

CPP film

CPP film, also known as cast polypropylene film, is a polypropylene film produced by the casting process. It is divided into general CPP (GCPP), aluminized grade CPP (MCPP) and cooking grade CPP (RCPP) films. Wide application: Due to the above advantages, CPP film is widely used in the packaging of textiles, flowers, food, and daily necessities. In addition, CPP film also has the characteristics of lower cost, higher output, higher stiffness than PE film, excellent water vapor and odor barrier, can be used as a composite material base film, and can be metallized.

Category: CPP filmOpen full product page - ×

Metallized CPP film

Metallized CPP film is a film made of polypropylene material with special process and special specifications, which belongs to high-end CPP film products. Its main feature is the metallization treatment, that is, a layer of metal, usually aluminum, is plated on the surface of the film through a special process to enhance the barrier performance and aesthetics of the product. This treatment not only enhances the physical properties of the film, such as heat seal strength, barrier and aesthetics, but also provides additional functional properties, such as barrier ability to oxygen and water molecules, thereby extending the shelf life of food and other products. Metallized CPP film is usually used in application scenarios that require high barrier properties, such as high-end food packaging, pharmaceutical packaging, etc., to ensure product quality and safety.

Category: CPP filmOpen full product page - ×

Retortable CPP film (RCPP)

Retortable CPP film is a film with good heat sealing properties, mainly used for food packaging. The thickness of retortable CPP film is generally between 60 and 80 μm, and it can withstand high-temperature cooking at 121°C for 30 minutes. It has good oil resistance and air tightness, as well as high heat sealing strength. This film is particularly suitable for the inner layer of meat packaging. Due to its excellent heat resistance and oil resistance, it can maintain the freshness and safety of food. In addition, retortable CPP film also has good heat sealing properties, which can maintain the integrity and nutrition of food during high-temperature cooking.

Category: CPP filmOpen full product page - ×

CPP anti-fog film

CPP anti-fog film is a polypropylene film produced by a three-layer co-extrusion process and a cast film. It is corona treated on one or both sides and has a unique anti-fog function. It can prevent water vapor from forming fog on the surface of the film, thereby maintaining high transparency and good shelf performance and display. This film not only has good moisture resistance, heat resistance and easy heat sealing, but also has high slip and impact resistance, excellent antistatic properties, high strength when combined with other materials, and is particularly suitable for use in frozen environments. It can keep the packaged objects clear and visible and extend the shelf life.

Category: CPP filmOpen full product page

- ×

PVC film

PVC film, the main component is polyvinyl chloride. It is a synthetic material that is favored for its excellent performance and wide application. In the manufacturing process of PVC film, in addition to the main polyvinyl chloride component, other components are added to enhance its heat resistance, toughness, ductility, etc. The structure of this film includes the top layer of paint, the middle polyvinyl chloride and the bottom layer of back-coated adhesive. Due to its diverse uses and good performance, PVC film ranks second in global usage among various synthetic materials and is an ideal material for producing three-dimensional surface films.

Category: PVC filmOpen full product page - ×

PVC blister packaging

PVC blister packaging is a plastic product produced using the blister process, and these products are packaged through corresponding equipment. It is a packaging container that uses plastic as the main raw material and deforms plastic sheets into the desired shape through vacuum forming or mechanical forming. The production process of this packaging box includes mold making and processing, mold processing and drying, vacuum forming and packaging finishing. Blister molds generally include plaster molds, electroplated copper molds and aluminum molds. Among them, aluminum molds are often used in production with high requirements for product precision due to their high precision and long life. PVC blister packaging is suitable for packaging small daily necessities, small appliances, toys and other commodities.

Category: PVC filmOpen full product page - ×

PVC light film

PVC light film is a transparent and shiny film, which is usually achieved by mounting a layer of this transparent plastic film on paper products. This kind of film is divided into two types: “light film” and “matte film”. The light film has the characteristics of being transparent and bright. PVC light film is widely used, including but not limited to lamination technology, in which covering a layer of PVC light film on the surface of paper and other materials can significantly improve the appearance and protective performance of the product. In addition, PVC light film is often used in various packaging, advertising materials, display supplies, etc. due to its excellent transparency and gloss to increase product appeal and market competitiveness.

Category: PVC filmOpen full product page - ×

PVC crystal board

PVC crystal board is a new type of polymer material with the characteristics of high transparency, light weight, impact resistance, corrosion resistance, and easy processing. It not only has many advantages of glass, such as high transparency, light weight, softness, heat resistance, cold resistance, strong acid and alkali resistance, heavy pressure resistance, anti-aging, good light transmittance, long service life, etc., but also has the advantages of not easy to break and not easy to scratch. Therefore, PVC crystal board is widely used in various commercial and home decoration fields, such as construction, furniture, automobiles and other fields. It is a high-quality plastic composite material with a smooth surface, bright and transparent, no cracks, no bubbles, uniform color, high resilience and folding and compression resistance, which can be suitable for a variety of environments. These characteristics of PVC crystal board make it a material that combines beauty and practicality, which is both decorative and can meet various functional needs.

Category: PVC filmOpen full product page - ×

PVC milky white film

The characteristics of PVC milky white film are mainly reflected in its physical properties, application areas and some specific performances. First of all, the color of PVC milky white film is usually milky white and has a certain degree of transparency. This color and transparency make it visually attractive and can meet the aesthetic needs of different application scenarios. In addition, the surface of PVC milky white film has a certain gloss, which increases its visual appeal.

Category: PVC filmOpen full product page - ×

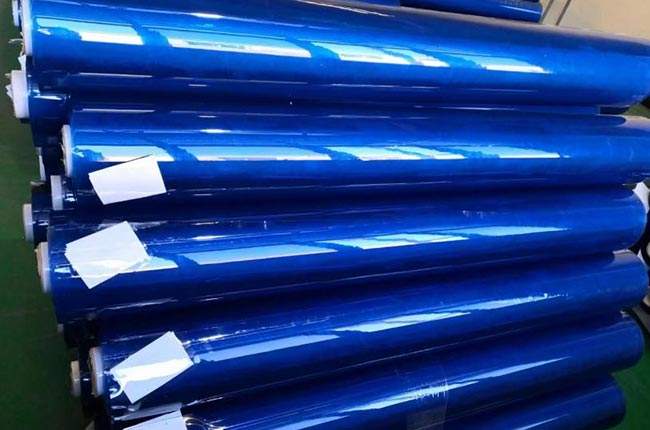

PVC blue film

PVC blue film is a kind of protective film, mainly made of polyvinyl chloride (PVC) material, named for its unique blue color. This protective film is widely used in various fields due to its excellent durability, plasticity and relatively low cost. In addition, PVC blue film also has the characteristics of acid and alkali resistance, scratch resistance, anti-static, bubble elimination, high light transmittance, etc., and can be customized according to different needs. Different thicknesses and layers can meet various special requirements. Dongguan Kaibei Special Adhesive Products Co., Ltd. and Dongguan Kaibei’s agent Ridong SPV-224 blue film is a kind of PVC blue film, which is widely used in cutting protection for LED chips and other purposes.

Category: PVC filmOpen full product page

- ×

PE film

PE film, also known as polyethylene film, is a film produced from PE particles. There are many density types. Including low-density polyethylene (LDPE), high-density polyethylene (HDPE) and medium-density polyethylene (MDPE). These different types of polyethylene have their own unique physical and chemical properties according to their density and molecular structure, and are widely used.

Category: PE filmOpen full product page

- ×

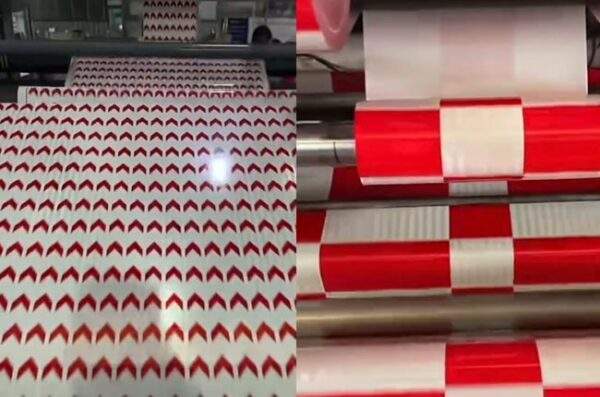

PET reflective tape

The microprismatic reflective tape is made by the refraction and total reflection principle of the cubic cone, and has a high reflectivity. With the continuous increase in the speed of automobiles and the complexity of road conditions, the application market of microprismatic reflective tape will become more and more extensive. The signs can be clearly seen in foggy, rainy, snowy and night days. Applied to: traffic and vehicle safety signs and markings, lane entrances, mailboxes, building corners, etc.

Category: PET reflective tapeOpen full product page