PET Blister Packaging Box

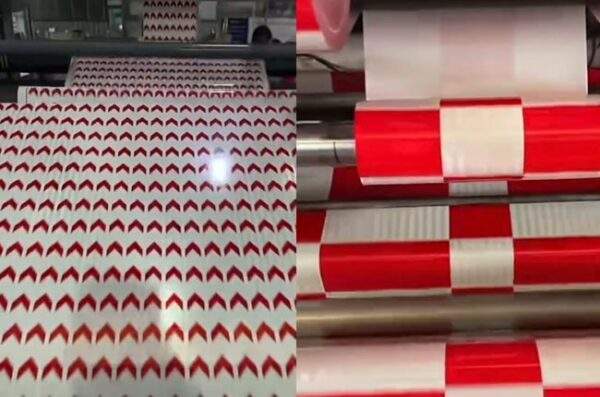

PET blister packaging box is a blister packaging box made of PET (polyethylene terephthalate) material. PET is a thermoplastic polyester, commonly known as polyester resin, with good physical properties and chemical stability, and is widely used in various packaging fields. Blister packaging box is a plastic product, and its raw materials include PVC, PS, PP, PET, PETG and flocking, antistatic, conductive and other materials. The production process of blister packaging box includes mold making and processing, softening treatment, vacuum forming and blister packaging finishing. Blister molds generally have three types: plaster molds, electroplated copper molds and aluminum molds. PET blister packaging boxes are characterized by high quality and low price. They can beautify products, improve product prices and image, and also have the function of displaying and protecting products. They are suitable for packaging of electronics, IT, industrial parts, toys, stationery, food, crafts and cosmetics.

Description

Features of PET blister packaging

- It has excellent transparency and smoothness, good display effect, excellent surface decoration performance, can be printed without surface treatment, easy to emboss patterns, and easy to metalize (vacuum metallization layer). In addition, PET blister boxes also have good mechanical strength, good barrier properties to oxygen and water vapor, good chemical resistance, and can withstand corrosion from a variety of chemical substances. It is also non-toxic and has reliable hygienic properties. It can be used for packaging food, drugs and medical equipment, and can be sterilized by Y-rays. PET sheets are considered to be an ideal packaging material that meets ROSH environmental protection requirements. They have good adaptability to environmental protection and can be recycled economically and conveniently. When their waste is incinerated, no harmful substances that harm the environment are produced.